MIL-DTL-23053/10D

Example: Black, 2.000 inch (50.80 mm) as supplied ID sleeving shall be

identified as M23053/10-012-O.

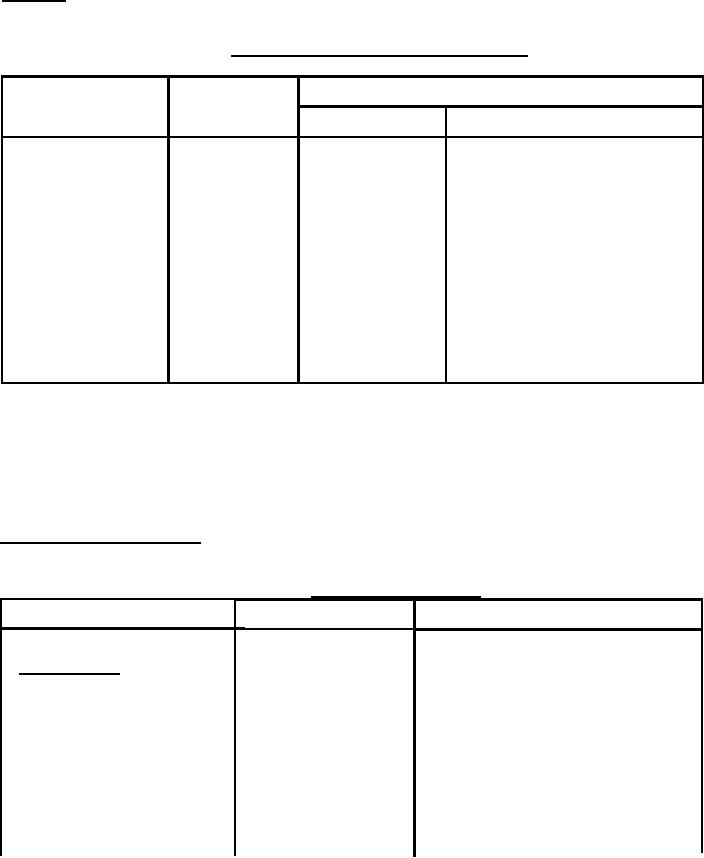

Construction details, inches (mm). 1/

TABLE I.

Military

As supplied

After unrestricted shrinkage

part number 3/

ID minimum

ID maximum

Wall thickness 2/

M23053/10-OO1-0

.125(3.18)

.071(1.80)

.020

±

.006(.508

±

.152)

M23053/10-O02-0

.250(6.35)

.035

±

.010(.889

±

.254)

.143(3.63)

M23053/10-O03-0

.375(9.53)

.040

±

.O1O(1.O16

±

.254)

.214(5.44)

M23053/10-O04-0

.500(12.70)

.286(7.27)

.048

±

.015(1.219

±

.381)

M23053/10-O05-0

.625(15.88)

.052

±

.015(1.321

±

.381)

.357(9.07)

M23053/10-O06-0

.750(19.05)

.057

±

.015(1.448

±

.381)

.428(10.87)

M23053/10-O07-0

.875(22.23)

.500(12.70)

.065

±

.015(1.651

±

.381)

M23053/10-O08-0

1.000(25.40)

.570(14.48)

.070

±

.020(1.778

±

.508)

M23053/10-O09-0

1.250(31.75)

.714(18.14)

.087

±

.O2O(2.21O

±

.508)

M23053/10-010-O

1.500(38.10)

.857(21.77)

.095

±

.020(2.413

±

.508)

M23053/10-011-O

1.750(44.45)

.107

±

.020(2.718

±

.508)

1.000(25.40)

M23053/10-O12-0

2.000(50.80)

1.140(28.96)

.110

±

.020(2.794

±

.508)

1/ Diameter limits for the object to be enclosed shall be as recommended

in technical data.

2/ Wall thickness values are less when shrinkage is restricted.

3/ The color code identified is the standard color.

Unrestricted shrinkage:

Test method 4.6.5.2 200° ± 2°C (392° ± 4°F) for 10

minutes.

TABLE II.

Physical properties.

Characteristic

Requirement

Test procedure and conditions

As supplied:

ID, minimum

Table I

4.6.3

Heat shock

No cracks,

4.6.8 300° ± 4°C

(572° ± 7.2°F)

flowing or

dripping

No mandrel bend

4.6.12.2 ASTM D412

Tensile stress

1,000(6.9)

at 100 percent,

psi (MPa), maximum

2