MIL-DTL-23053/4D

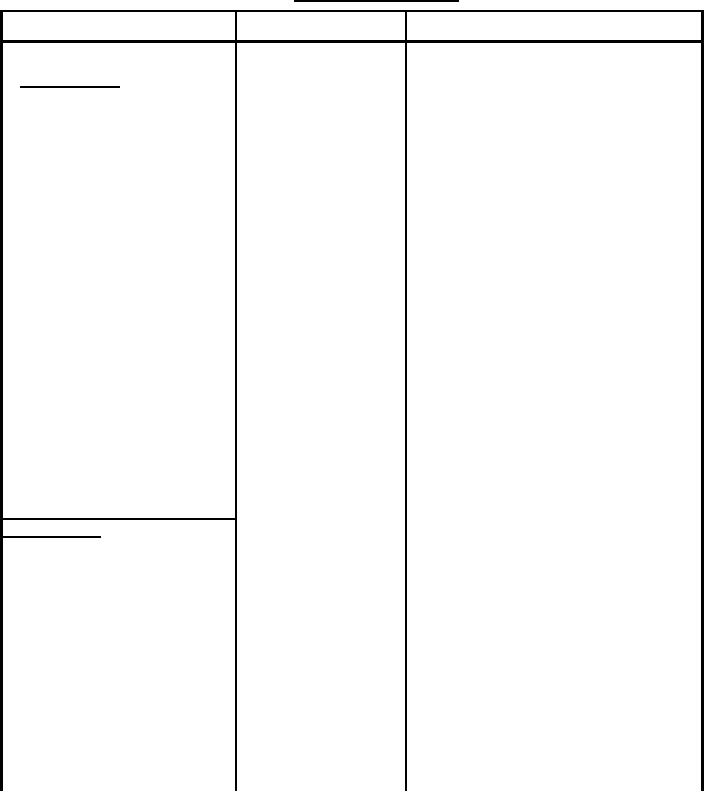

TABLE II. Physical properties.

Characteristic

Requirement

Test procedure and condition

As supplied:

ID, minimum

Table I

4.6.3

Cold impact

No cracking

4.6.7.2 ASTM D746,

-55° ± 2°C (-67 ± 4°F)

Heat shock

4.6.8 250° ± 3°C

No cracks,

(482° ± 6°F) 1/

flowing or

dripping of

outerwall

Sealing efficiency

No openings

2/

(Classes 1 and 3

on reheat

only)

Class 1 - 25,000

Secant modulus, psi

4.6.12.1, ASTM D882, 2

(172) minimum

(MPa)

percent strain

Cl 2 & 3 - 25,000

(172) maximum

4.6.15 175° ± 2°C

Color stability

Pass

(347° ± 4°F), 24 hours

After unrestricted

shrinkage:

4.6.3

ID, maximum

Table I

4.6.3

Wall thickness

Table I

Tensile strength,

Classes 1 & 2 -

4.6.12, ASTM D638, 20

psi (MPa), minimum

1,500 (10.3)

inches/minute

Class 3 - 1,300

(9.0)

Ultimate elongation,

4.6.12, ASTM D638, 20

Classes 1 & 2 -

percent minimum

inches/minute

200

Class 3 - 250

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business