MIL-DTL-23053/12C

3/ The asterisk (*) in the part number shall be replaced by color code

designators (see 1.2.2).

Unrestricted shrinkage:

Test method 4.6.5; 350° ± 4°C (662° ± 8°F) for 10

minutes.

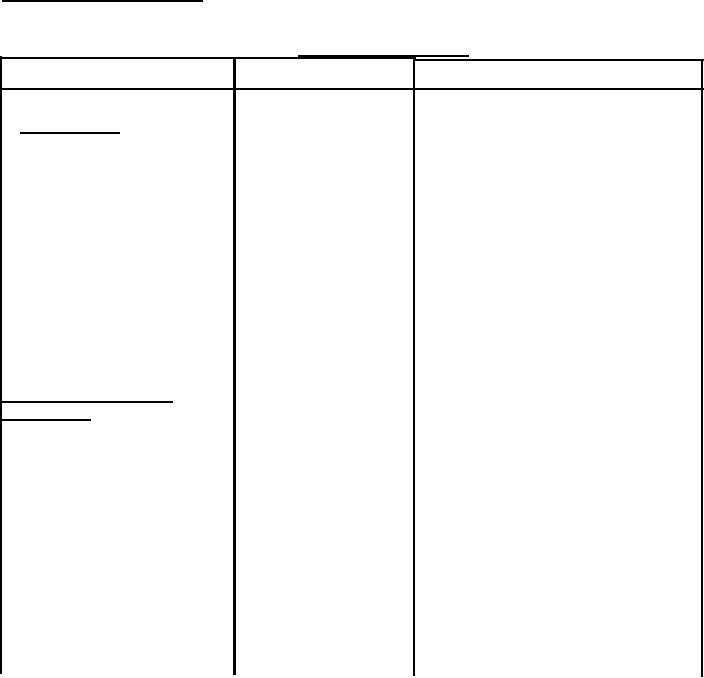

TABLE II.

Physical

properties.

1/

Characteristic

Requirement

Test procedure and conditions

As supplied:

ID, minimum

Table I

4.6.3

Heat shock

No cracks,

4.6.8 400° ± 5°C

flowing or

(752° ± 9°F)

dripping

Restricted

Pass

4.6.6.1.2 350° ± 4°C

shrinkage

(662° ± 7.2°F),

5 minutes

Voltage withstand

Pass

4.6.6.2

After unrestricted

shrinkage:

ID, maximum

Table I

4.6.3

Wall thickness

Table I

4.6.3

Tensile strength,

2,500(17.3)

4.6.13 ASTM D638, 2

psi (MPa), minimum

inches/minute

Ultimate elongation,

200

4.6.13 ASTM D638, 2

percent, minimum

inches/minute

Dielectric strength,

800(31.5)

4.6.2 ASTM D2671

volts/mil (Kv/mm),

minimum

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business