MIL-DTL-23053/6D

3/ The color codes cited above for Class 1 sleevings are preferred

acquisition colors. Class 1 sleevings are also available in other

colors (see 1.2.1)

Unrestricted

shrinkage:

Test method 4.6.5, 200° ± 2°C (392° ± 4±F) for 3

minutes.

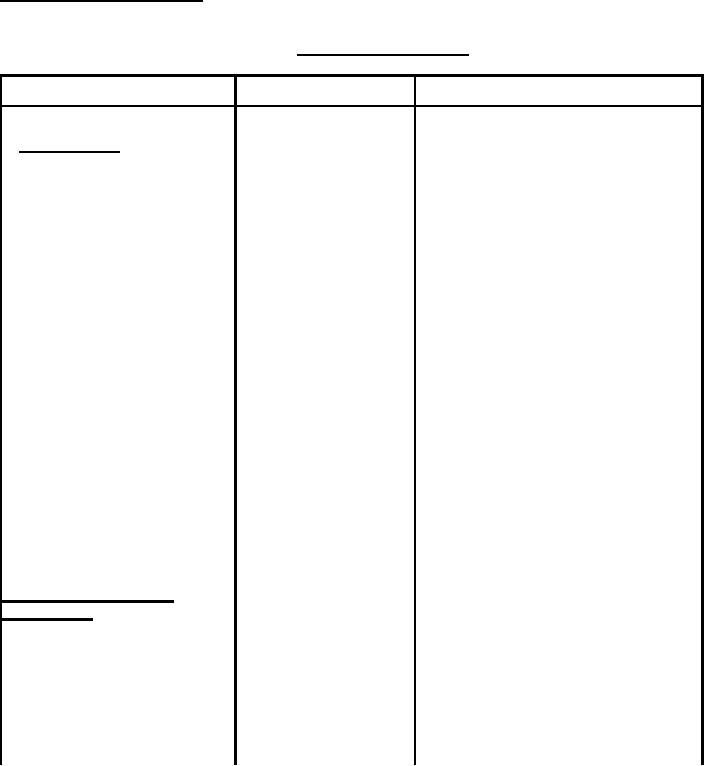

Physical properties. 1`/

TABLE II.

Characteristic

Requirement

Test procedure and condition

As supplied:

ID, minimum

4.6.3

Table I

Heat shock

4.6.8 250° ± 3°C

No cracks,

flowing or

(482° ± 6°F)

dripping

Secant modulus,

4.6.12.1, 2 percent strain,

25,000 (172.4)

ASTM D882

psi (MPa), minimum

4.6.15 175° ± 2°C

Color stability

Pass

(347° ± 4°F), 24 hours

4.6.3.3

Concentricity

70% minimum

4.6.16, 175° ± 2°C

Clarity stability,

Pass

Class 2

(347° ± 4°F), 24 hours

4.6.6.1.1 175° ± 2°C

Restricted shrinkage

No cracks

(347° ± 4°F)

Voltage withstand

4.6.6.2

Pass

After unrestricted

shrinkage:

4.6.3

ID, maximum

Table I

4.6.3

Wall thickness

Table I

4.6.13 ASTM D638, 2

Tensile strength,

2,000(13.8)

psi (MPa), minimum

inches/minute

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business