A-A-56023B

requirements of the uncured insulating compounds are shown in table I. The physical and

electrical requirements of the cured insulating compounds are shown in table II. Conditioning

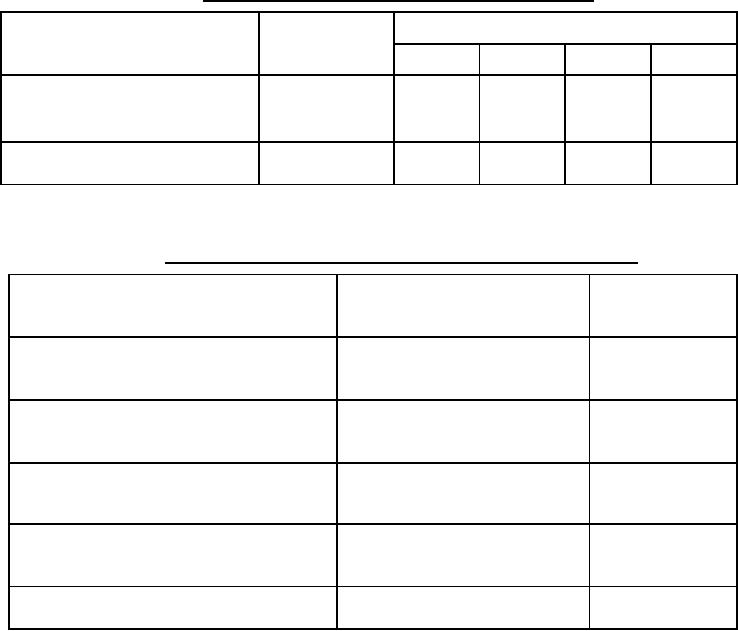

TABLE I. Physical requirements, uncured insulating compounds.

Requirement

Conditioning

Requirement values

procedure 1

Type I

Type II

Type III

Type IV

(see table III)

Uncatalyzed, viscosity, average,

A

200/500

200/600

300/900

80/250

minimum/maximum, poises

Catalyzed, pot life, minimum,

A

0.5

0.5

0.5

0.5

hours

1

Conditioning procedure A: As received, no special conditioning. Conditioning procedure E: Temperature

conditioned (see table II, footnotes 1, 2 and 3).

TABLE II. Physical and electrical requirements, cured insulating compounds.

Conditioning procedures 1 2 3

Requirement

Requirement

(see table III)

values,

all types

Hardness shore A, average,

A

35/70

minimum/maximum

E-70/232 °C + E-1/-24 °C

35/70

E-1/-54 °C + E-1/24 °C

35/70

Tensile strength, average, minimum,

A

300

pounds force per square inch (lbf/in 2)

E-70/232 °C + E-1/24 °C

150

E-1/-54 °C + E-1/24 °C

300

Tear strength, average, minimum, pounds

A

15

force per inch of thickness (lbf/in)

Elongation, average, minimum, percent

A

100

E-70/232 °C

75

E-1/-54 °C

100

Dielectric strength, average, minimum,

A

350

volts per mil, approx. 75 mil sheet

1

Proceed with conditioning procedures after curing insulating compounds for not less than 72 hours at 24 °C ±3 °C.

2

Conditioning procedure A: As received, no special conditioning.

3

Conditioning procedure E: Temperature conditioned; encoding definition is a capital letter indicating type of

conditioning, a number indicating the duration of the conditioning in hours, and a number indicating the temperature

in degrees C. A sequence of conditions is denoted by a "+" sign between conditions, see ASTM D618, "Standard

Practice for Conditioning Plastics for Testing".

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business