MIL-DTL-23053/1C

Physical properties. 1/ - Continued

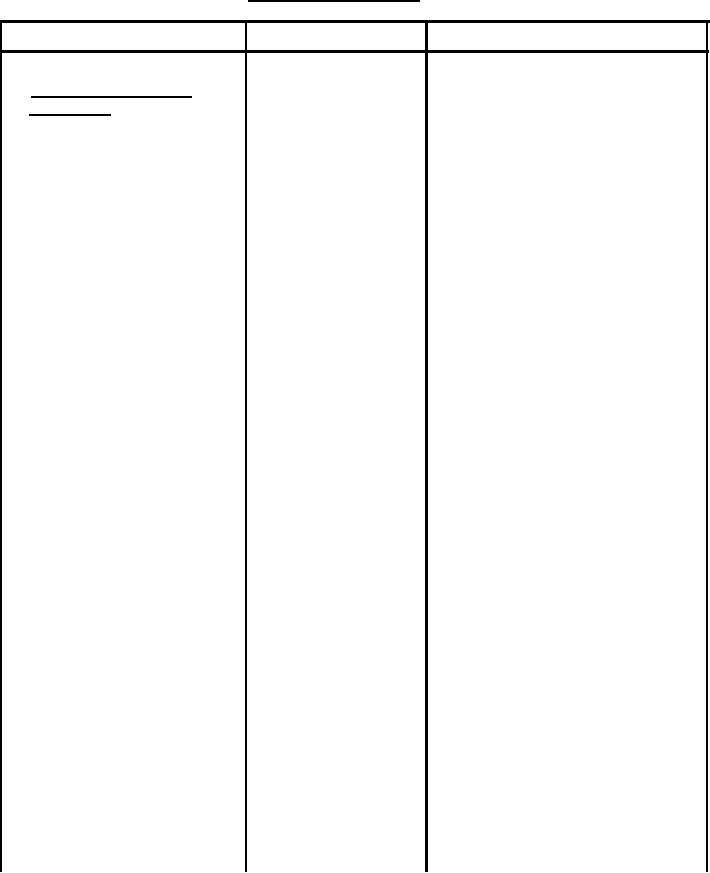

TABLE II.

Characteristic

Requirement

Test Procedure and condition

After unrestricted

shrinkage:

4.6.3.1.2

ID, maximum

Table I

4.6.3.2

Wall thickness

Table I

4.6.13 ASTM D412

Tensile strength,

1,500 (10.3)

psi (MPa), minimum

Ultimate elongation,

225

4.6.13 ASTM D412

percent, minimum

4.6.12.2 ASTM D412

Tensile stress,

1,500 (10.3)

at 200 percent

elongation

psi (MPa), maximum

4.6.2 ASTM D2671

Dielectric strength,

300 (11.8) - Up

volts/roil (Kv/mm), min

to 0.070 wall

thickness

200 (7.8) -

0.070 and above

1 x 1011

4.6.2 ASTM D876

Volume resistivity,

Ohm-CM, minimum

4.6.10.1 and 4.6.10.2 at

Corrosion

No pitting or

corrosion

150° ± 2°C (302° ± 4°F)

for 16 hours.

Water absorption,

4.6.2 ASTM D570,

1.0

percent, maximum

24 hrs at 23°C

Heat resistance,

4.6.9 Class 1:

100° ± 2°C

(212° ± 4°F),

96 hours;

properties after:

Class 2: 121°

± 2°C

Tensile strength,

1,200

(250° ± 4°F),

168 hours

psi (MPa), minimum

Ultimate elongation,

Class 1 - 150

percent, minimum

Class 2 - 175

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business