MIL-DTL-23053/13B

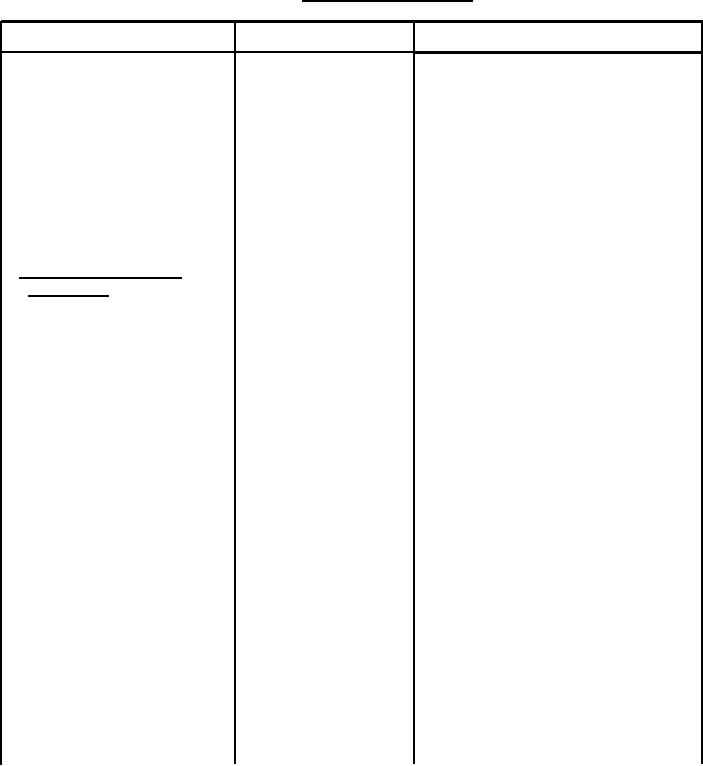

TABLE II.

Physical properties.

Characteristic

Requirement

Test procedure and conditions

Heat shock

No cracking,

4.6.8 300° ± 5°C

(572° ± 9°F)

flowing or

dripping

Restricted

4.6.6.1.2 200° ± 2°C

No cracks

shrinkage

(392° ± 4°F)

Voltage with-

Pass

4.6.6.2

stand

After unrestricted

shrinkage:

ID, maximum

Table I

4.6.3

Wall thickness

Table I

4.6.3

Tensile stength, psi

1,200 (8.2)

4.6.13, ASTM D412

(MPa), minimum

Ultimate elongation,

4.6.12, ASTM D412

250

percent,

Tensile stress

4.6.2 ASTM D412

2,000(13.8)

at 200 percent

elongation, psi

(MPa), maximum

4.6.2 ASTM D2671

Dielectric strength,

200(7.9)

volts/roil, (Kv/mm),

minimum

109

Volume resistivity,

4.6.2 ASTM D876

Ohm-cm, minimum

4.6.10.1 and 4.6.10.2

Corrosion

No corrosion or

175° ± 2°(347° ± 4°F) for

pitting

16 hours.

3