MIL-DTL-23053/14B

Example: 0.500 inch (12.7 mm) as supplied ID ETFE sleeving shall be

identified as M23053/14-006-C.

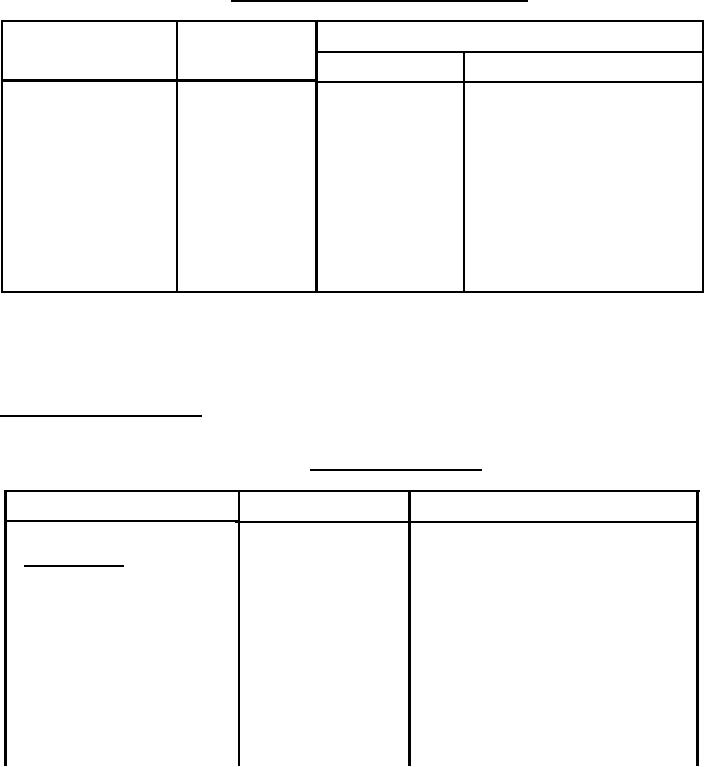

Construction details, inches (mm). 1/

TABLE I.

Military

As supplied

After unrestricted shrinkage

part number

ID minimum

ID maximum

Wall thickness 2/

M23053/14-001-C

.093

(2.4)

.062

(1.6)

.010

±

.002(.25

±

.05)

M23053/14-002-C

.125

(3.2)

.010

±

.002(.25

±

.05)

.083

(3.1)

M23053/14-003-C

.187

(4.7)

.011

±

.002(.28

±

.05)

.125

(3.2)

M23053/14-004-C

.013

±

.003(.33

±

.08)

.166

(4.2)

.250

(6.4)

M23053/14-005-C

.375

(9.5)

.013

±

.003(.33

±

.08)

.250

(6.4)

M23053/14-006-C

.500

(12.7)

.013

±

.003(.33

±

.08)

.345

(8.3)

M23053/14-007-C

.500

(12.7)

.750

(19.0)

.018

±

.004(.46

±

.10)

M23053/14-008-C

1.000

(25.4)

.022

±

.004(.56

±

.10)

.665

(16.7)

M23053/14-009-C

1.250

(31.8)

.030

±

.004(.80

±

.10)

.835

(21.2)

M23053/14-010-C

.030

±

.004(.80

±

.10)

1.500

(38.0)

1.000

(25.4)

1/ Diameter limits for object to be enclosed shall be as recommended in

technical data.

2/ Wall thickness dimensions are less when shrinkage is restricted.

Unrestricted shrinkage:

Test method 4.6.5; 175° ± 1°C (347° ± 2°F) for 10

minutes.

TABLE II.

Physical properties.

Characteristic

Requirement

Test procedure and conditions

As supplied:

ID minimum

Table I

4.6.3

Restricted shrinkage

No cracks

4.6.6.12 175° ± 2°C

(347° ± 4°F)

Voltage withstand

Pass

4.6.6.2

Clarity stability

Pass

4.6.16 175° ± 1°C

(347° ± 2°F), 24 hours

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business