MIL-DTL-23053/15B

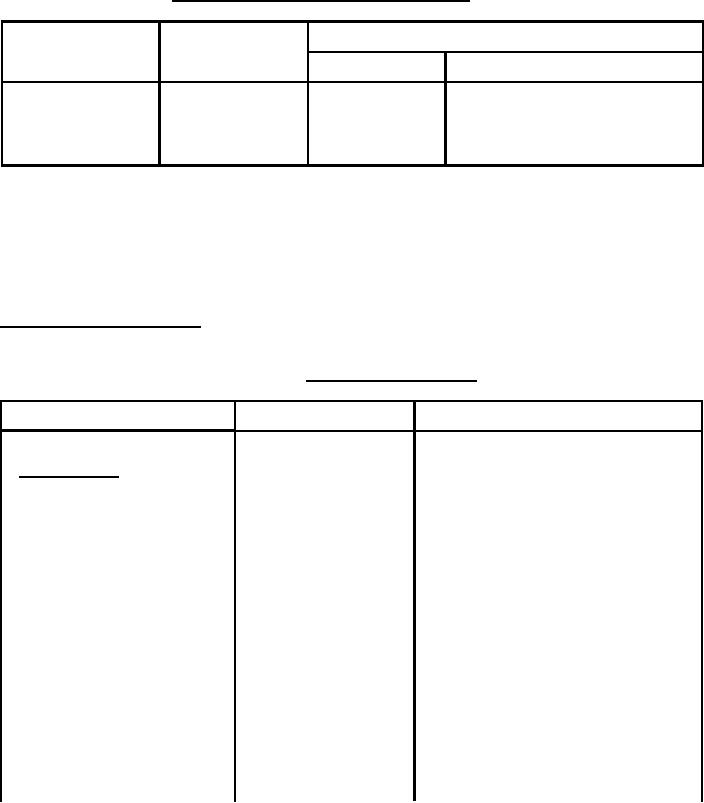

TABLE I.

Construction details, inches (mm)).

1/ - Continued

Military

As supplied

After unrestricted shrinkage

part number

ID minimum 3/

ID maximum

Wall thickness nominal

M23053/15-205-0

1.500(38.1)

.500(12.7)

.120(3.05)

M23053/15-206-0

1.700(43.2)

.500(12.7)

.140(3.56)

M23053/15-207-0

2.700(68.6)

.900(22.9)

.155(3.44)

M23053/15-208-0

2.000(50.8)

.750(19.1)

.140(3.6)

1/ Diameter limits for objects to be

enclosed shall be

as recommended in

technical data.

2/ Wall thickness values are less when shrinkage is restricted.

3/ As supplied ID is for uncoated product. An allowance of approximately

.050 inch (1.3 mm) may be necessary depending on coating.

Unrestricted shrinkage:

Test method 4.6.5.2; 200° ± 2°C (392° ± 4°F) for 10

minutes maximum.

TABLE II. Physical properties.

Characteristic

Test procedure and conditions

Requirement

As supplied:

ID, minimum

Table I

4.6.3

Low temperature

No cracking

4.6.7.1 -55° ± 2°C

flexibility

(-67° ± 4°F)

Heat shock

No cracking,

4.6.8 225° ± 3°C

flowing or

(437° ± 6°F)

dripping of

outer wall

Secant modulus,

25,000(172.4)

4.6.12.1, 2 percent

psi (MPa),

strain, ASTM D882

maximum

4.6.15 175° ± 2°C

Color stability

Pass

(347° ± 4°F) 24 hours

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business