MIL-DTL-23053/8C

Example: 0.093 inch (2.36 mm) as supplied ID sleeving shall be identified as

M23053/8-O03-C.

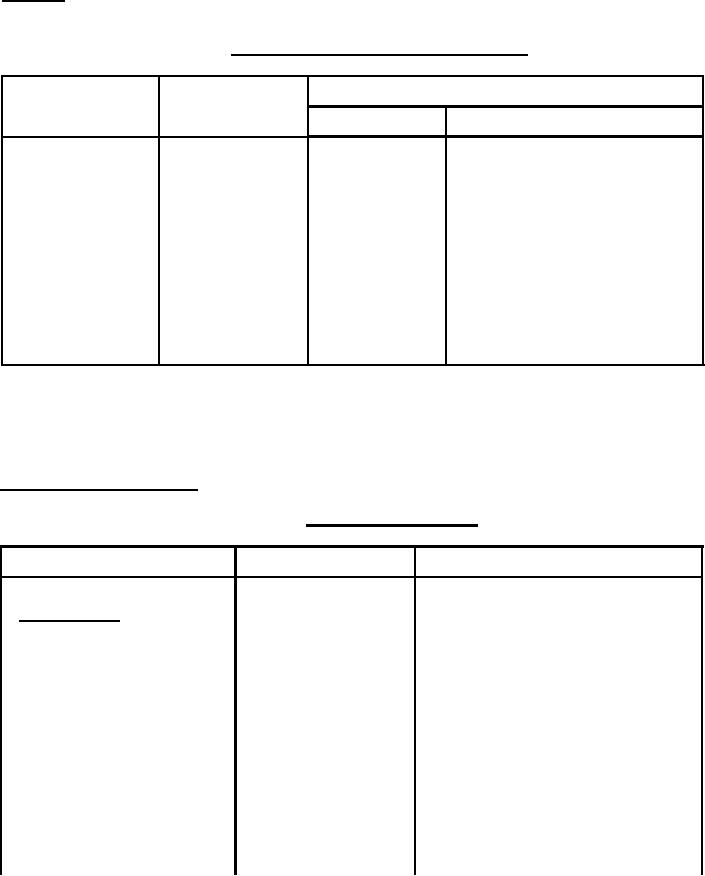

TABLE I.

Construction details, inches (mm). 1/

After unrestricted shrinkage

Military

As supplied

part number

ID minimum

Wall thickness 2/

ID maximum

.010

±

.002

(.254

±

.051)

M23053/8-001-C

.046

(1.17)

.023

(.58)

.010

±

.002

(.254

±

.051)

.063

(1.60)

M23053/8-002-C

.031

(.79)

.010

±

.002

(.254

±

.051)

.093

(2.36)

M23053/8-O03-C

.046

(1.17)

.010

±

.002

(.254

±

.051)

.125

(3.18)

.062

(1.58)

M23053/8-004-C

.010

±

.002

(.254

±

.051)

.187

(4.75)

.093

(2.36)

M23053/8-005-C

.250

(6.35)

.012

±

.003

(.305

±

.076)

M23053/8-006-C

.125

(3.18)

.012

±

.003

(.305

±

.076)

.375

(9.53)

M23053/8-007-C

.187

(4.75)

.012

±

.003

(.305

±

.076)

M23053/8-008-C

.500

(12.70)

.250

(6.35)

.017

±

.003

(.432

±

.076)

.375

(9.53)

M23053/8-009-C

.750

(19.05

.019

±

.003

(.483

±

.076)

.500

(12.7)

M23053/8-010-C

1.000

(25.40)

.020

±

.003

(.508

±

.076)

M23053/8-011-C

.750

(19.1)

1.500

(38.10)

1/ Diameter limits for object to be enclosed shall be as recommended in

technical data.

2/ Wall thickness values are less when shrinkage is restricted.

Unrestricted shrinkage:

Test method 4.6.5, 200° ± 2°C (392 ± 4°F) for 3 minutes.

TABLE II. Physical properties.

Characteristic

Requirement

Test procedure and conditions

As supplied:

4.6.3

ID, minimum

Table I

4.6.8 300° ± 4°C

Heat shock

No cracks,

(572° ± 7.2°F)

flowing or

dripping

4.6.12.1 ASTM D882,

Secant modulus, psi

120,000 (690)

2 percent strain

(MPa), minimum

4.6.6.1.1 175° ± 2°C

Restricted shrinkage

No cracks

(347° ± 4°F)

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business