MIL-DTL-23053/8C

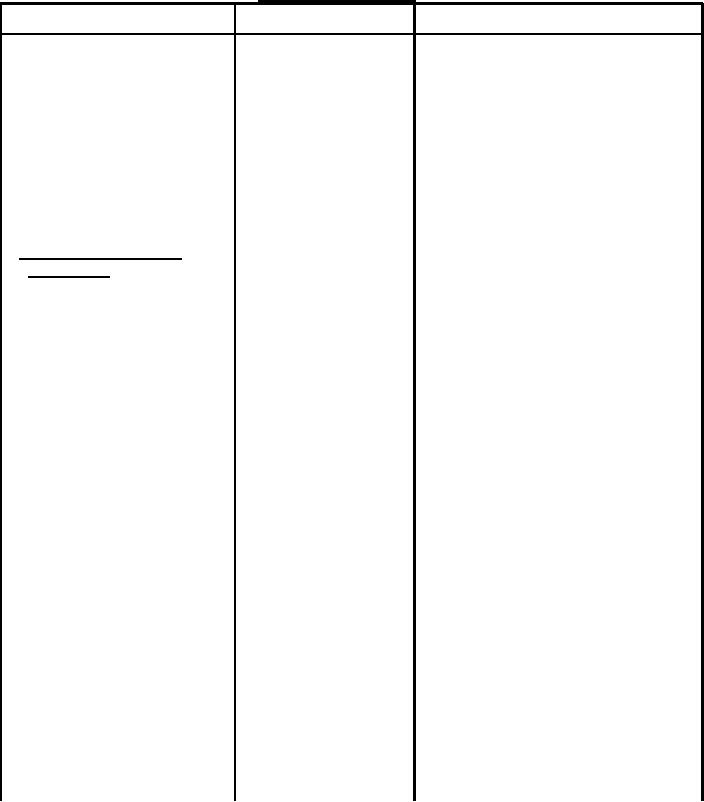

TABLE II. Physical properties. - Continued

Characteristic

Test procedure and conditions

Requirement

Voltage withstand

Pass

4.6.6.2

Clarity stability,

Pass

4.6.16 175° ± 2°C

(347° ± 4°F) for 24 hours

Concentricity

4.6.3.3

70% min.

Crystalline melt

150 (302)

ASTM D4951 1/

point, °C (°F), min

After unrestricted

shrinkage:

ID, maximum

Table I

4.6.3

Table I

Wall thickness

4.6.3

Low temperature

No cracking

4.6.7.1 -55° ± 1±C

flexibility 2/

(-67° ± 2°F)

Tensile strength,

5,000 (34.5)

4.6.13 ASTM D638,

psi (MPa), minimum

2 inches/minute

Ultimate elongation,

4.6.13 ASTM D638, 2

150

percent, minimum

inches/minute

4.6.2 ASTM D2671

Dielectric strength,

Sizes to .500 -

volts/roil (Kv/mm),

800 (31.5);

minimum

Sizes over .500-

600 (23.6)

1013

Volume resistivity,

4.6.2 ASTM D876

Ohm-cm, minimum

Specific gravity,

4.6.2 ASTM D792

1.8

max.

4.6.2 ASTM D570, 24 hrs at

Water absorption,

0.5

percent, maximum

23°C

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business