MIL-PRF-46846D

4.4.2.3.2 Conditioning procedure. The conditioning procedures required, with the

exception of Condition A, shall be indicated by the following combinations of symbols. The

numbers shall be separated from each other by a slant mark.

a. A capital letter indicating the type of conditioning.

b. A number indicating the duration of the conditioning in hours.

c. A number indicating the conditioning temperature in degrees Celsius.

4.4.2.3.3 Conditioning tolerance. Unless otherwise specified (see 6.2), the conditioning

temperature tolerance and additional testing information shall be as specified in table IV.

4.5 Tests. Testing to determine compliance with the requirements of tables II and III shall

be in accordance with the methods specified in the tables and in accordance with the paragraphs

of this specification called out in tables II and III.

4.5.1 Examination of product. The heat-shrinkable tubing, molded parts and extruded

shapes shall be carefully examined to determine conformance to all requirements for which a

specific test method is not specified herein (see 3.11).

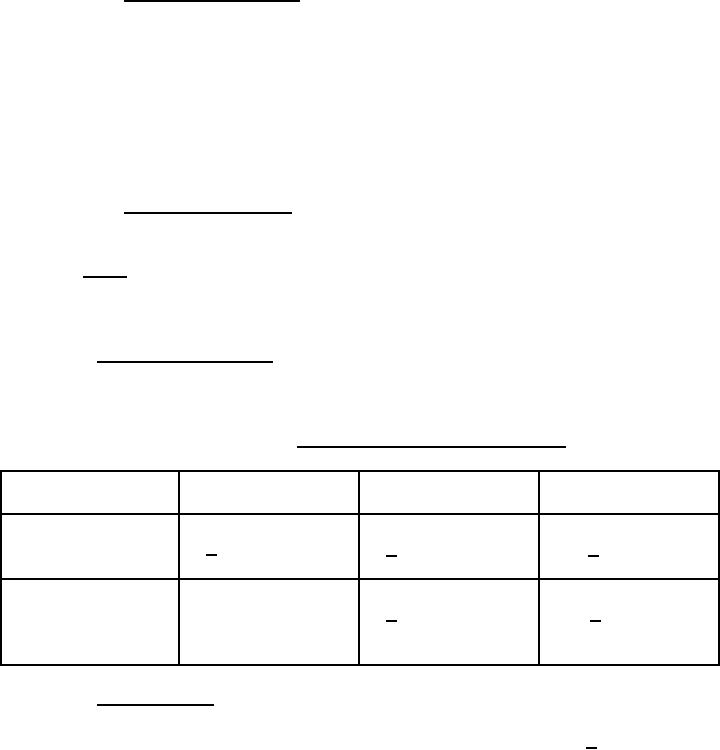

TABLE IV. Conditioning and testing information.

Conditioning

Conditioning

Tolerance

Testing temperature

procedure

time

temperature

+ 2C

23 + 2C

E (high temperature)

+ 1 hour

+ 2C

-55 + 2C

E (low temperature)

+ 30 minutes

or - zero

4.5.2 Elastic memory. A 6 inch by 0.125 inch specimen (see 4.4.1.2) shall be marked with

two parallel gauge lines 1 inch apart in the central portion of the specimen. The 2-inch portion of

the specimen including both gauge lines shall then be heated for 1 minute at 150 + 2°C for

types I, II, IV, and VI class 2, for 5 minutes at 200 5°C for type III class 2, removed from the

heat and stretched within 10 seconds until the gauge lines are 3 inches apart for types I and IV

class 2, 4 inches apart for type III class 2, or 5 inches apart for type VI class 2. The extended

specimen shall then be cooled in water for 1 minute at 20 to 30°C, released from tension, removed

from the water, and wiped dry. After 24 hours at room temperature, the distance between the

gauge lines shall be measured and recorded as the extended length. The portion of the specimen

including both gauge lines shall then be reheated for 1 minute at the temperature specified above,

removed from the heat and allowed to retract. The specimen again shall be cooled for 1 minute in

water at 20 to 30C, removed from the water, and wiped dry. The distance between gauge lines

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business