MIL-DTL-23053/7C

Physical properties. - Continued

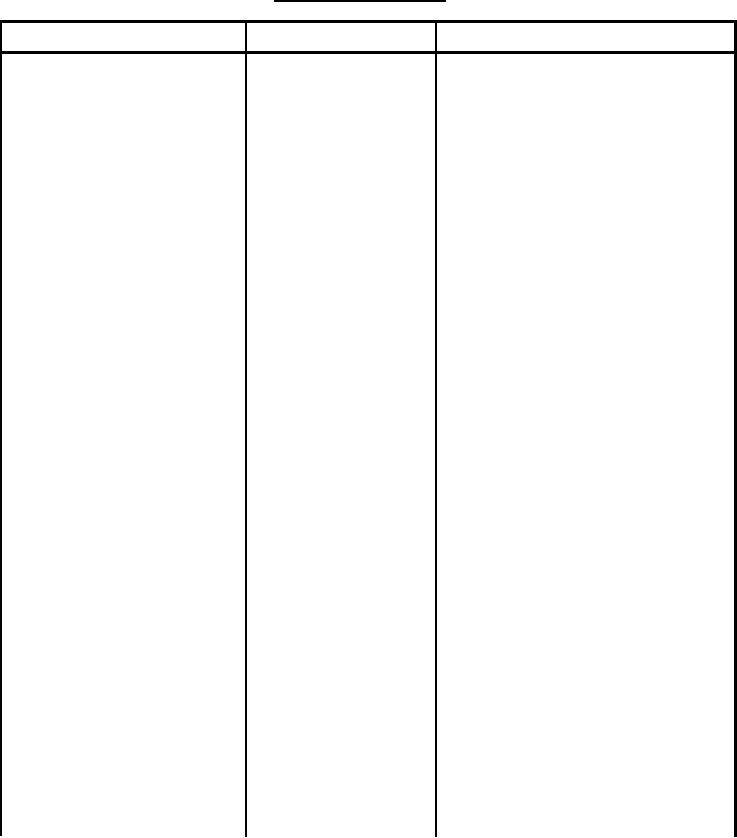

TABLE II.

Characteristic

Requirement

Test procedure and conditions

Seam strength,

25 (450)

4.6.2 ASTM D882, Method A

Class 1, PPI

(Kg/m), minimum

Tensile strength,

20,000 (138)

4.6.13 ASTM D638, 20

psi (MPa), minimum

inches/minute

Ultimate elongation,

50

4.6.13 ASTM D638, 20

percent, minimum

inches/minute

Dielectric strength,

2,500 (98.4)

4.6.2 ASTM D2671

volts/roil (Kv/mm)

minimum

1014

Volume resistivity,

4.6.2 ASTM D876

Ohm-cm, minimum

Specific gravity,

1.3

4.6.2 ASTM D792

minimum

Corrosion

4.6.10.1 and 4.5.10.2

No corrosion

155 ± 20C (311° ± 4°F),

16 hours

Low temperature

No cracking

4.6.7.1 -60° ± 1°C

flexibility

(-76° ± 2°F)

Water absorption,

0.8

4.6.2 ASTM D570, 24 hrs

percent, maximum

at 23°C

Heat resistance,

4.6.8 150° ± 2°C

properties after:

(302° ± 4°F), 336 hours

Tensile strength,

Class 1 - 18,000

4.6.13 ASTM D638, 20

psi (MPa), minimum

inches/minute

(124)

Class 2 - 13,000

(89.7)

Ultimate elongation,

4.6.13 ASTM D638, 20

Class 1 - 55

percent, minumum

Class 2 - 40

inches/minute

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business